Rollon, a specialist developer of linear movement options, has launched its new Cobot Switch Unit (CTU), designed to push the boundaries of collaborative robotic functions.

With a sequence of key enhancements, the newest CTU mannequin provides improved flexibility, simpler integration, and elevated efficiency, making it the best resolution for automation processes requiring prolonged attain.

The brand new CTU introduces a variety of updates geared toward simplifying set up and maximizing effectivity. A transition to a brand new motor helps guarantee decreased lead occasions, as it’s available in inventory. Moreover, the adoption of a 220V energy provide – matching the voltage of Common Robots – eliminates the necessity for industrial voltage, simplifying integration and decreasing electrical complexities.

The revised match between CTU and robotic sizes improves compatibility, now supporting your complete Common Robots vary, together with the UR20 and UR30. The combination of the R-Sensible actuator additional enhances system stiffness and cargo capability, serving to guarantee larger reliability in automation environments.

Andrea Tosi, VP expertise at Rollon, says: “Our newest CTU displays Rollon’s dedication to steady innovation and customer-driven design.

“By optimizing the system structure, now we have created an answer that delivers seamless integration with Common Robots, larger flexibility, and improved effectivity. With this launch, we’re empowering producers with a sturdy, plug-and-play movement resolution that extends the capabilities of cobots like by no means earlier than.”

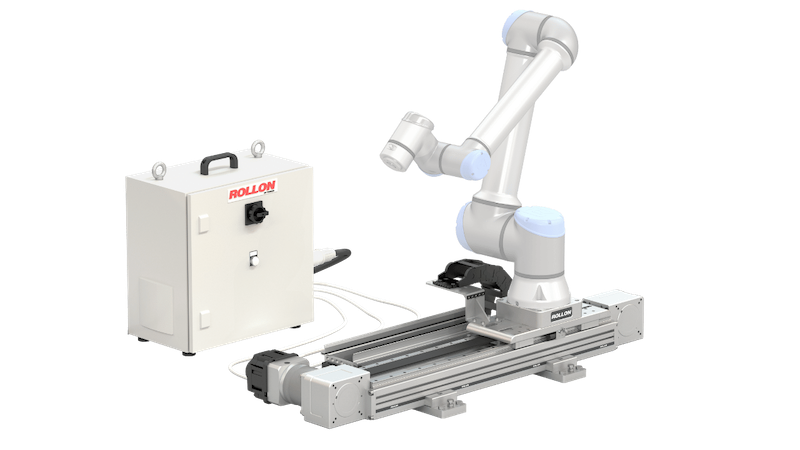

Rollon’s CTU is a turnkey system that features an actuator, a gearbox, motor, electrical cupboard, and Rollon’s URCap software program, permitting intuitive programming immediately from the Common Robots train pendant. This allows customers to manage each the robotic and the switch unit by the identical interface, eliminating the necessity for extra programming experience.

With a steel-reinforced belt drive, extruded aluminium profile, and recirculating ball guides, the CTU provides excessive stiffness, light-weight building, and strokes of as much as 5500 mm, with extensions obtainable upon request. The system additionally options numerous equipment for clean integration, making it straightforward for patrons to tailor the setup to their particular necessities.

Designed for duties comparable to gentle materials dealing with, meeting, pick-and-place, and packaging, CTU’s compact design, straightforward set up, and versatile horizontal or vertical mounting assist adaptability throughout various automation environments.

With these developments, Rollon says it continues to “set new requirements in linear movement options”, offering producers with cutting-edge automation expertise.