Because the world’s reliance on fossil fuels diminishes, there’s an escalating urgency to transition in the direction of renewable power sources, and lithium-ion batteries (LIBs) have emerged as a cornerstone on this shift. The importance of LIBs extends nicely past shopper electronics, permeating by industries that embody electrical automobiles, renewable power techniques, and sensible applied sciences. Nonetheless, the complexity of large-scale battery building reveals a big hurdle—environment friendly electrolyte filling and wetting processes.

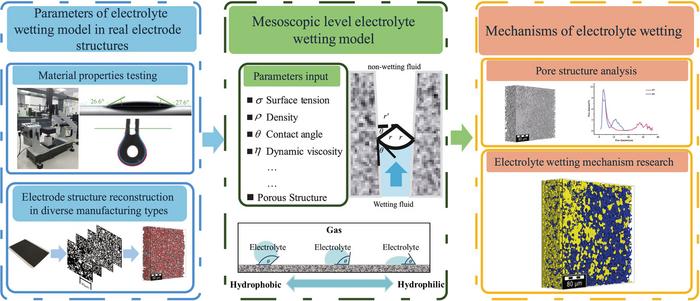

Groundbreaking analysis initiated by a workforce at Tsinghua College endeavors to handle this essential bottleneck within the realm of battery engineering. The examine focuses on the intricate interaction between electrode structure and electrolyte wetting, two elements that dramatically affect the efficiency capabilities of lithium-ion batteries. By searching for to know these relationships extra totally, the researchers purpose to propel developments that would improve the performance and longevity of those very important power storage techniques.

Central to the examine is the usage of superior X-ray computed tomography, a cutting-edge imaging method that permits the reconstruction of three-dimensional buildings inside battery electrodes. This subtle method supplies unparalleled insights into the microstructural options that govern how electrolytes work together with electrode surfaces. By peerlessly evaluating the size and geometries concerned, it turns into attainable to pinpoint essential variables that considerably affect electrolyte wetting.

The researchers uncovered that the manufacturing course of profoundly influences how nicely the electrolyte can permeate electrode supplies. Particularly, changes in calendering stress—the pressure utilized to compress the electrode layers—together with variations within the lively materials content material, have been discovered to have an effect on porosity ranges inside the electrodes. This nuanced understanding opens up manifold potentialities for engineers to control the structure of LIBs throughout manufacturing.

A posh scenario arises because of the interactions between porosity, permeability, and capillary motion. When calendering stress is elevated or when the proportion of lively supplies in an electrode rises, the porosity tends to lower. This discount can improve the capillary forces at play, an impact that would enhance electrolyte distribution beneath sure situations. Nonetheless, if not managed precisely, this will likely additionally impair the general wetting efficiency, leaving researchers with a multifaceted problem to navigate.

The analysis offered an in-depth examination of the causes behind incomplete electrolyte wetting. Two important culprits have been recognized: first, the partial closure of pores, which may occur through the calendering course of, restricts electrolyte entry. Second, non-wetting section gases can turn into trapped within the electrode buildings. These gases act as boundaries that forestall optimum contact between the electrolyte and electrode supplies, limiting the effectiveness of your entire battery system.

Notably, the examine in query goes past mere qualitative discussions; it integrates quantitative assessments as nicely. By measuring permeability ranges and capillary forces, the researchers furnish producers with empirical knowledge. This info might be strategically employed to refine manufacturing methodologies, finally resulting in extra environment friendly and cost-effective battery manufacturing processes that additionally improve efficiency metrics.

The implications of those findings are important for the longer term trajectory of battery expertise. By offering a scientific basis for manufacturing optimization, the analysis opens a number of promising pathways for engineering developments that would redefine how lithium-ion batteries are constructed. As an example, one avenue consists of the event of optimum geometric configurations for electrodes and separators to maximise floor space and interplay potentials through the wetting section.

Furthermore, the institution of multi-scale, multi-physics numerical fashions may facilitate complete modeling of assorted influencing mechanisms. These superior simulations would permit for an intensive examination of how a number of variables work together inside the advanced environments of battery techniques. The expectation is that such fashions may result in extra predictable outcomes in battery efficiency.

One other fascinating prospect lies within the potential creation of macro-scale course of simulation fashions primarily based on micro-scale insights. As these macro fashions evolve, they could yield predictive capabilities relating to saturation immersion instances that exquisitely align with manufacturing processes, finally contributing to reductions in operational prices.

Moreover, the analysis introduces a novel concept: implementing vibration inputs through the immersion course of to expel trapped gases. This innovation may markedly enhance the amount of electrolyte that may infiltrate the electrodes, paving the best way for even larger effectivity in battery meeting and efficiency.

What emerges from this pioneering analysis is extra than simply technical findings; it’s a name to motion for the battery manufacturing neighborhood. The examine constructively challenges standard approaches and encourages a concentrate on detailed microstructural elements which have beforehand been missed. Because the demand for high-energy-density batteries continues to develop, significantly in sectors very important to a sustainable future, equivalent to electrical automobiles and renewable power techniques, these insights will turn into more and more important.

In conclusion, the excellent examination of electrolyte wetting mechanisms yields transformative implications for the manufacturing of lithium-ion batteries. The synthesis of superior imaging methods with empirical assessments permits for a profound understanding of essential relationships driving battery efficiency. This analysis paints a promising future, suggesting that as we push the boundaries of power storage expertise, improved manufacturing practices may yield an period of extra environment friendly, higher-performing, and dependable battery techniques that maintain the potential to energy our clear power aspirations.

Topic of Analysis: Not relevant

Article Title: Unraveling mechanisms of electrolyte wetting course of in three-dimensional electrode buildings: Insights from practical architectures

Information Publication Date: 17-Jan-2025

Net References: DOI

References: Nationwide Pure Science Basis of China, Shanghai Science and Expertise Improvement Fund

Picture Credit: Credit score: GREEN ENERGY AND INTELLIGENT TRANSPORTATION

Key phrases

Lithium ion batteries, Electrodes, Manufacturing

Tags: superior imaging methods in battery researchelectric car battery technologyelectrode structure optimizationelectrolyte wetting challengesinnovative battery engineering researchlithium-ion battery advancementsmicrostructural evaluation of batteriesnext-generation power storage systemsovercoming battery building obstaclesperformance enhancement of lithium-ion batteriesrenewable power storage solutionsTsinghua College battery examine

Because the world’s reliance on fossil fuels diminishes, there’s an escalating urgency to transition in the direction of renewable power sources, and lithium-ion batteries (LIBs) have emerged as a cornerstone on this shift. The importance of LIBs extends nicely past shopper electronics, permeating by industries that embody electrical automobiles, renewable power techniques, and sensible applied sciences. Nonetheless, the complexity of large-scale battery building reveals a big hurdle—environment friendly electrolyte filling and wetting processes.

Groundbreaking analysis initiated by a workforce at Tsinghua College endeavors to handle this essential bottleneck within the realm of battery engineering. The examine focuses on the intricate interaction between electrode structure and electrolyte wetting, two elements that dramatically affect the efficiency capabilities of lithium-ion batteries. By searching for to know these relationships extra totally, the researchers purpose to propel developments that would improve the performance and longevity of those very important power storage techniques.

Central to the examine is the usage of superior X-ray computed tomography, a cutting-edge imaging method that permits the reconstruction of three-dimensional buildings inside battery electrodes. This subtle method supplies unparalleled insights into the microstructural options that govern how electrolytes work together with electrode surfaces. By peerlessly evaluating the size and geometries concerned, it turns into attainable to pinpoint essential variables that considerably affect electrolyte wetting.

The researchers uncovered that the manufacturing course of profoundly influences how nicely the electrolyte can permeate electrode supplies. Particularly, changes in calendering stress—the pressure utilized to compress the electrode layers—together with variations within the lively materials content material, have been discovered to have an effect on porosity ranges inside the electrodes. This nuanced understanding opens up manifold potentialities for engineers to control the structure of LIBs throughout manufacturing.

A posh scenario arises because of the interactions between porosity, permeability, and capillary motion. When calendering stress is elevated or when the proportion of lively supplies in an electrode rises, the porosity tends to lower. This discount can improve the capillary forces at play, an impact that would enhance electrolyte distribution beneath sure situations. Nonetheless, if not managed precisely, this will likely additionally impair the general wetting efficiency, leaving researchers with a multifaceted problem to navigate.

The analysis offered an in-depth examination of the causes behind incomplete electrolyte wetting. Two important culprits have been recognized: first, the partial closure of pores, which may occur through the calendering course of, restricts electrolyte entry. Second, non-wetting section gases can turn into trapped within the electrode buildings. These gases act as boundaries that forestall optimum contact between the electrolyte and electrode supplies, limiting the effectiveness of your entire battery system.

Notably, the examine in query goes past mere qualitative discussions; it integrates quantitative assessments as nicely. By measuring permeability ranges and capillary forces, the researchers furnish producers with empirical knowledge. This info might be strategically employed to refine manufacturing methodologies, finally resulting in extra environment friendly and cost-effective battery manufacturing processes that additionally improve efficiency metrics.

The implications of those findings are important for the longer term trajectory of battery expertise. By offering a scientific basis for manufacturing optimization, the analysis opens a number of promising pathways for engineering developments that would redefine how lithium-ion batteries are constructed. As an example, one avenue consists of the event of optimum geometric configurations for electrodes and separators to maximise floor space and interplay potentials through the wetting section.

Furthermore, the institution of multi-scale, multi-physics numerical fashions may facilitate complete modeling of assorted influencing mechanisms. These superior simulations would permit for an intensive examination of how a number of variables work together inside the advanced environments of battery techniques. The expectation is that such fashions may result in extra predictable outcomes in battery efficiency.

One other fascinating prospect lies within the potential creation of macro-scale course of simulation fashions primarily based on micro-scale insights. As these macro fashions evolve, they could yield predictive capabilities relating to saturation immersion instances that exquisitely align with manufacturing processes, finally contributing to reductions in operational prices.

Moreover, the analysis introduces a novel concept: implementing vibration inputs through the immersion course of to expel trapped gases. This innovation may markedly enhance the amount of electrolyte that may infiltrate the electrodes, paving the best way for even larger effectivity in battery meeting and efficiency.

What emerges from this pioneering analysis is extra than simply technical findings; it’s a name to motion for the battery manufacturing neighborhood. The examine constructively challenges standard approaches and encourages a concentrate on detailed microstructural elements which have beforehand been missed. Because the demand for high-energy-density batteries continues to develop, significantly in sectors very important to a sustainable future, equivalent to electrical automobiles and renewable power techniques, these insights will turn into more and more important.

In conclusion, the excellent examination of electrolyte wetting mechanisms yields transformative implications for the manufacturing of lithium-ion batteries. The synthesis of superior imaging methods with empirical assessments permits for a profound understanding of essential relationships driving battery efficiency. This analysis paints a promising future, suggesting that as we push the boundaries of power storage expertise, improved manufacturing practices may yield an period of extra environment friendly, higher-performing, and dependable battery techniques that maintain the potential to energy our clear power aspirations.

Topic of Analysis: Not relevant

Article Title: Unraveling mechanisms of electrolyte wetting course of in three-dimensional electrode buildings: Insights from practical architectures

Information Publication Date: 17-Jan-2025

Net References: DOI

References: Nationwide Pure Science Basis of China, Shanghai Science and Expertise Improvement Fund

Picture Credit: Credit score: GREEN ENERGY AND INTELLIGENT TRANSPORTATION

Key phrases

Lithium ion batteries, Electrodes, Manufacturing

Tags: superior imaging methods in battery researchelectric car battery technologyelectrode structure optimizationelectrolyte wetting challengesinnovative battery engineering researchlithium-ion battery advancementsmicrostructural evaluation of batteriesnext-generation power storage systemsovercoming battery building obstaclesperformance enhancement of lithium-ion batteriesrenewable power storage solutionsTsinghua College battery examine