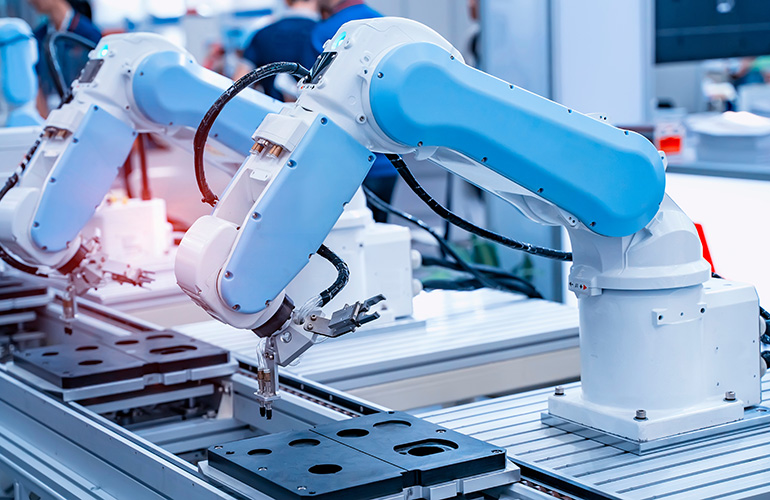

Contract engineering companies can assist speed up robotic improvement and deployment, in response to SKA Robotics. Supply: Adobe Inventory

Think about you’re tasked with constructing a robotic—an autonomous system designed for industrial precision. You’ve spent months simply looking for the requisite expertise. Your mechanical engineering staff was comparatively simple to assemble, however relating to the specialised talent units wanted — reinforcement studying (RL), synthetic intelligence integration, and superior robotic notion — you’re hitting a wall.

Consultants command premium salaries — typically as much as $250,000 for lead RL roles — and your finances is rapidly ballooning. Then you definitely uncover that two stealth-mode startups are planning to launch a competing product inside months.

Sound acquainted? That is precisely why outsourcing or partnering with specialised contract engineering companies is commonly the neatest transfer. Even the largest names—from NASA to Apple—have traditionally introduced in exterior specialists to sort out the hardest technical challenges. It’s not only a cash play; it’s about velocity, flexibility, and confirmed experience.

As SKA Robotics founder Spencer Krause defined in weblog put up “Why Corporations Ought to Contract Out Robotics Programs Improvement” and in a latest interview with R&D World: “A lot of right now’s companies appear to hesitate relating to outsourcing tough engineering duties. They might fear that utilizing contractors will diminish their perceived worth. Nevertheless, relating to robotics, nothing could possibly be farther from the reality.”

Krause and the staff at his firm provided insights on avoiding widespread pitfalls that in-house robotics groups usually face. Additionally they added perspective on how a contract engineering agency can assist you keep away from them.

Pitfall 1: Getting slowed down by useful resource constraints

Constructing a robotic isn’t low-cost or fast. You want money, time, and other people—plenty of ’em. Corporations usually assume they will simply hand the challenge to their current staff, solely to appreciate they’re quick on gear, finances, or bandwidth. Delays pile up, prices balloon, and all of the sudden your “easy” robotics challenge is draining your group.

In consequence, initiatives can get sophisticated, even for area specialists. “Assembly advanced robotics deadlines is advanced for me,” stated Nathan George, CEO of Void Robotics, on a podcast with Krause.

“I attempt to resolve actually, actually laborious issues, however I can’t essentially assure a deadline simply,” he added. “I’ve to do fastened prices to verify it doesn’t go an excessive amount of over finances.”

Outsourcing repair: Contract engineering companies come ready-made with the instruments, expertise, and processes you want—no scrambling to purchase software program licenses, no have to search out gear or reassign your inside groups. They transfer quick, which implies fewer delays and smoother budgeting.

Case research instance: Siemens Power wanted a custom-built robotic for generator upkeep on a good timeline. By partnering with a specialised exterior engineering agency, it deployed a completely operational robotic inside 4 months.

This allowed Siemens Power to keep away from disassembling large-scale turbines—saving about three days of downtime for every deployment and preserving roughly $1.73 million in alternative value each time the robotic was used.

Pitfall 2: Scuffling with labor shortages

Scarce engineering expertise poses challenges for each lengthy and quick initiatives, says SKA Robotics. Supply: Adobe Inventory

Discovering robotics professionals is brutal proper now. Even huge corporations can’t rent sufficient expert engineers, and coaching your individual could be a sluggish, dangerous course of.

Worse but, if it’s a one-off challenge, you might find yourself saddled with a specialised staff you don’t want long-term. Based on Locomation CTO Tekin Meriçli, even a $74 million funding spherical can really feel like “peanuts” once you’re scaling an autonomous car startup: you rapidly discover ways to stretch each greenback—and in addition how laborious it may be to draw the appropriate folks.

In one other episode, George talked about a method of managing dozens of interns to deal with a few of these gaps, although that comes with its personal challenges.

“I don’t know too many corporations that might belief an intern to be in control of their gross sales,” famous Krause, who acknowledged that the association may work. Unpaid or low-paid engineering interns can scale back labor prices, however they usually require important coaching and supervision, typically consuming extra senior workers time than they save.

Outsourcing repair: Contract engineering crews are stacked with specialists who’ve already minimize their tooth on advanced robotics. You mainly get a cohesive staff with out combing via job boards or coping with prolonged onboarding. And when your challenge is completed, they’re off the payroll—no costly severance packages or idle specialists.

Case research instance: In mining and development, SKA Robotics has collaborated on initiatives involving autos with load capacities starting from below 500 lb. (226.7 kg) to greater than 3 million lb. (1.3 million kg).

In a single case, the corporate started detailed testing on miniature, scaled-down fashions together with a 1:12 scale model of a blast gap driller. This system enabled exact calibration of autonomous navigation programs earlier than deploying the know-how onto full-sized equipment.

Pitfall 3: Getting caught in approval purgatory

Greater corporations have larger processes: extra paperwork, extra gatekeepers, extra pink tape. That’s effective in principle—till it grinds your robotics timeline to a halt.

Instance: The headhunter Greg Toroosian (Try Episode 149 of Krause’s podcast) highlights how inside forms can sluggish all the pieces down, particularly in massive organizations that require a number of sign-offs simply to buy a single part or proceed to the following improvement part.

Outsourcing repair: Excessive-end contract engineering companies dwell and die by quick decision-making. They don’t wade via the identical hierarchy you do. They will quickly pivot, approve new components, or add new expertise on the fly, permitting your challenge to maintain buzzing—even whereas your inside groups are nonetheless filling out varieties.

Case research instance: On a multi-robot photo voltaic subject development program for Sarcos Expertise and Robotics Corp., exterior programs and notion engineers maintained necessities, developed algorithms, and managed subsystem motion diagrams with out being slowed down by inside sign-off delays.

Their capacity to adapt rapidly at every improvement stage helped hold the general challenge on observe and minimized downtime attributable to bureaucratic slowdowns.

Pitfall 4: Sudden technical difficulties

An AI-generated picture depicts a possible downside of extreme solder smoke throughout an electronics meeting course of. | Supply: Sora/OpenAI

Robotics is a beast—{hardware}, software program, and controls all have to sync completely. “’Sudden technical difficulties’ can seem out of nowhere and tank your schedule,” famous Krause. A single {hardware} glitch can set you again months when you’re studying on the job.

Outsourcing repair: Seasoned contract engineers have seen all of it earlier than. They’ve wrangled these issues on prior gigs and may sort out them quick—usually borrowing classes from parallel industries. As an illustration, SKA Robotics has utilized area trade approaches to resolve advanced development robotic challenges.

Case research instance: One producer of blast gap drillers wanted a strong autonomous navigation answer. By partnering with a contract engineering agency that had deep expertise in distant management and GPS-based autonomy, the staff overcame sudden {hardware} integration points and collision-avoidance complexities.

The contractor’s fast response and prior information of comparable issues drastically diminished delays, permitting the car to drill holes and geotag them with minimal human oversight.

Pitfall 5: Missing in-house experience

Not each firm has a robotics wizard on workers, and that’s okay—till you soar headfirst into constructing a robotic requiring specialised algorithm design or superior controls engineering.

Outsourcing repair: Contract engineering companies deliver bundled experience—electrical, mechanical, controls, software program—below one roof. Hiring them sidesteps the necessity to attempt to rent and combine a half-dozen totally different specialists by yourself.

Case research instance: An organization growing a surgical robotic turned to an exterior staff when it wanted superior collision avoidance and tool-path “snap to” options. Inside a span of roughly 10 weeks, the exterior engineers delivered embedded software program that parsed STL recordsdata, managed real-time collision mitigation, and supplied a simulator for demonstration.

The agency’s prior experience in low-level chipset coding and robotics algorithms crammed vital information gaps for the consumer—and saved it months of in-house trial and error.

Pitfall 6: Overcommitting to non-recurring wants

The Mission Administration Triad—often known as the Triple Constraint—is typically humorously summarized as, “Good, quick, or low-cost: Choose two.” | Supply: Sora/OpenAI

Hiring full-time for a single robotics gig might be financially counterproductive. You possibly can find yourself locked right into a bloated payroll lengthy after your one-and-done challenge wraps.

Void Robotics’ George acknowledged that he tried to promote a common product at first however in the end shifted to working with a particular buyer in a leaner, extra incremental method.

“The associated fee to develop is difficult, so we’re doing it fairly slowly,” he recounted.

Outsourcing repair: Once you outsource, you’re paying for efficiency on a set timeline. As soon as the challenge is full, so is the contract. You don’t have to justify layoffs or discover busywork for newly employed specialists. It’s a clear break that retains your finances lean and your organizational construction steady.

Case research instance: A corporation wished a self-driving catamaran to autonomously gather water samples, a necessity that solely arose for particular analysis intervals. As an alternative of constructing a devoted maritime robotics division, it contracted out hull design, drive programs, and autonomy integration.

After profitable deployments in a number of areas, the corporate merely ended the contract, stopping pointless long-term payroll for a bespoke challenge.

SKA Robotics seems to be on the huge image

Krause famous that giant enterprises typically fear that outsourcing “diminishes” their very own inside worth. However main successes, from the Apollo Lunar Lander to the iPhone, show in any other case. The actual threat is burning time, cash, and morale whereas your staff struggles to resolve issues that specialists have seen and solved earlier than.

Trendy robotics requires a multidisciplinary method—mechanical engineering, controls, algorithm design, software program, and extra, reiterated SKA Robotics. Even with stellar in-house groups, unexpected snags like labor shortages, inside pink tape, and specialised information gaps can derail your launch. And in a world the place market home windows shut rapidly, that’s a threat few can afford.

Editor’s observe: This text was syndicated from The Robotic Report sibling web site R&D World.

Register now so you do not miss out!